How to fine balance a crank shaft

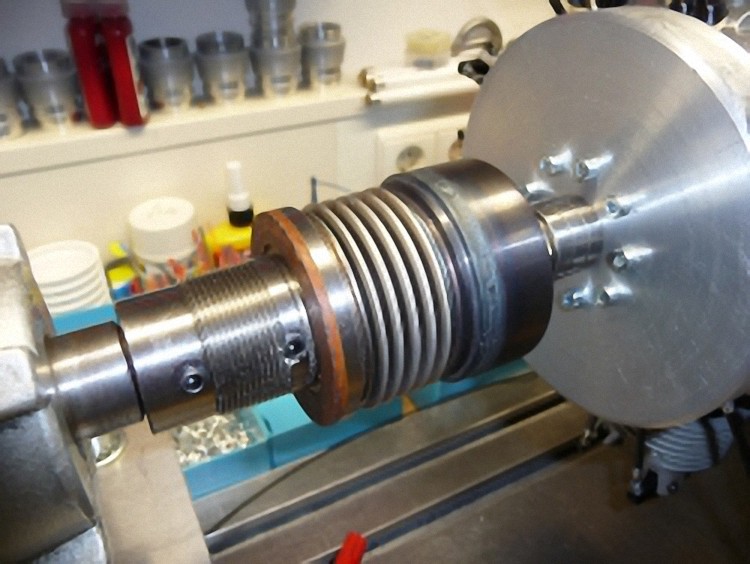

While constructing a crank shaft I weigh all movable parts (pistons, connecting rods, mother connecting rod, needle bearings, pins and connecting rod bolts). The total weight plus 20 % corresponds to the crank arm’s weight, i.e. at the moment the crank arm is definitely too heavy. I then install the crank shaft prototype into the radial engine.

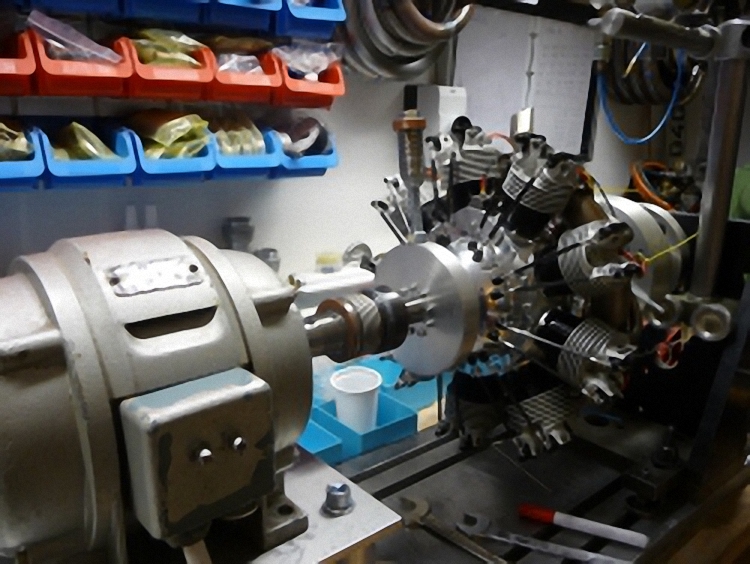

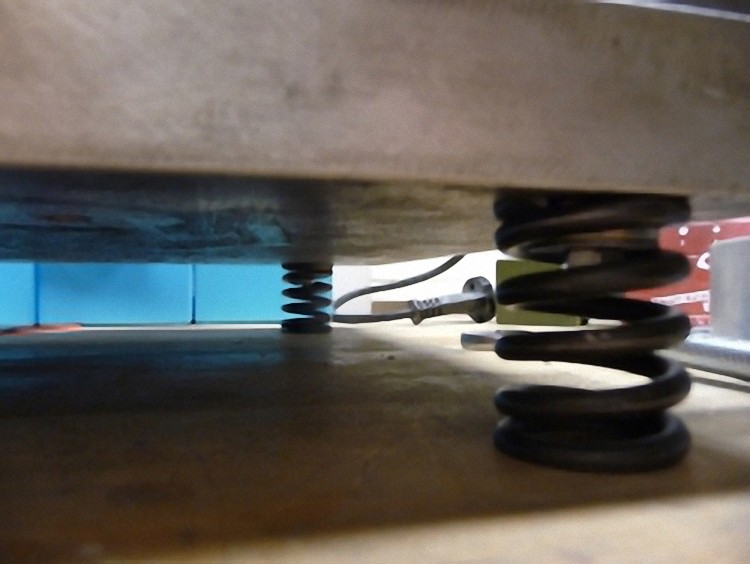

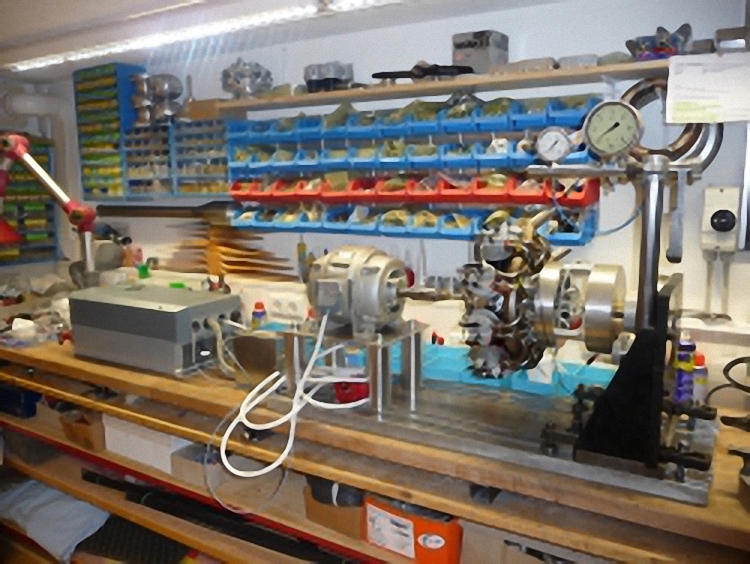

Then the functional radial engine is put to the dry running test with a 2PS electric engine. The radial engine is brought to a programmed speed ramp of 2000 rpm (70 Hz) without combustion. The electric engine is decoupled from the radial engine with a metal bar clutch. The radial engine is decoupled from the test bench with an oil bath. The whole test bench is mounted on springs and is therefore decoupled from the work bench.

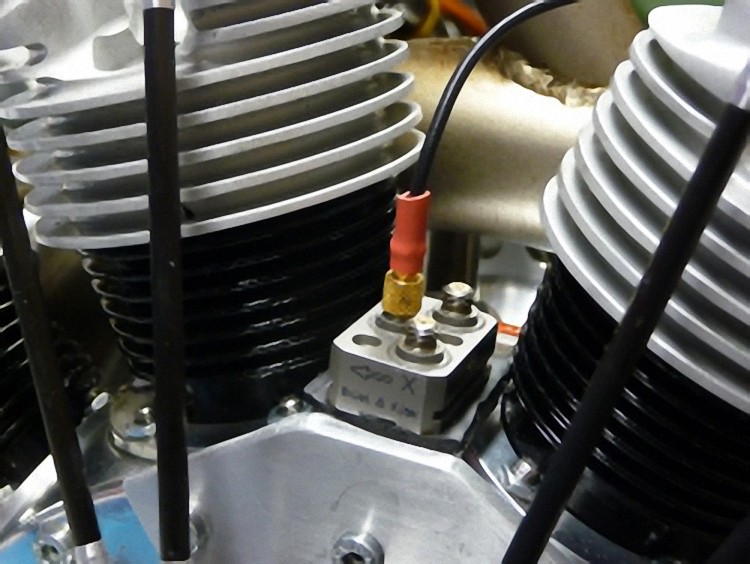

The imbalance is measured with a vibration sensor (quartz) on the engine case. The data are recorded on a high speed data logger. The speed ramp was programmed to 5 sec. startup (2000 rpm), and then 3 sec speed retaining and shutting down in 1 sec. At the same time 20.000 measurements per second were recorded. We measured vibrations of the first order = imbalance and vibrations of second order = cam disc speed.

The counterweight was attached from the outside to the position of the propeller fastener and optimized until the frequency measurement in the mV area exceeded the lowest amplitude upwards. 36 measurements were carried out and the counterweight changed in 1g intervals.

The determined counterweight is then converted to the crank arm and transcribed accordingly.