Seidel-UMS ST 9-90 Modification

The history

Friedrich Wolf asked us to check the functionality of his new SEIDEL UMS ST 9-90. We have already built a ring exhaust for the now historic ST 5-525 for Friedrich Wolf. Apparently he is confident of our radial engine competence.

During one of Mr. Seidel’s performances on a flight day Friedrich Wolf fell in love with this 9-cylinder engine. It is a perfect scale engine for a PZL M-18 Dromader. As it is produced in India, the price was very attractive. The engine demonstration run proved its functionality.

We were supposed to make a ring exhaust for this engine again. The little ring that SEIDEL offers as supplies isn’t suitable for a true to scale replica. Also, we were supposed to check why it wasn’t possible to adjust an even valve clearance. After every crank shaft rotation the first setting was extremely different. We were also asked if we could modify the high-gloss aluminum case with the engraving “Designed in Germany” into a real engine look. Equip the engine with carbon push rods and wire it completely with our Hölzl glow plug regulator “Star Glow”.

But of course we can!

We couldn’t set the valve clearance repeatable though. So we started to search for causes.

The disassembled engine shows a typical radial engine construction. Why some parts have obvious hammer marks – probably only the Indian precision mechanic knows.

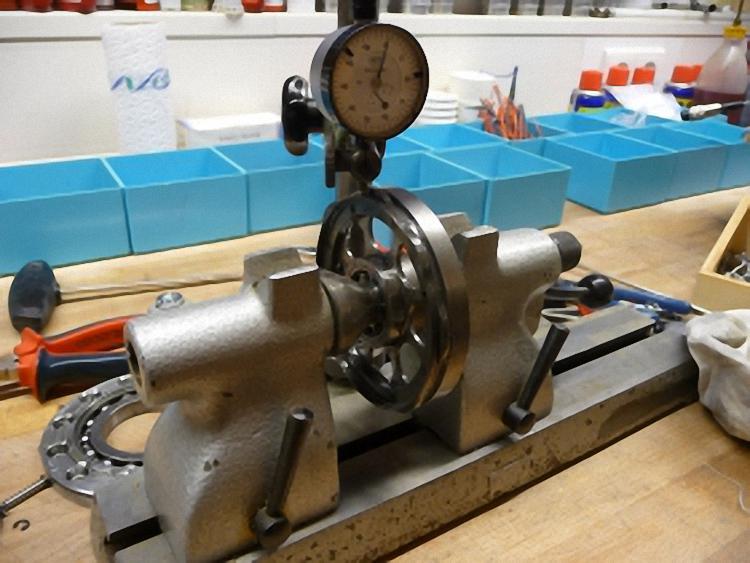

Measuring the cam disc, that drives the valve push rod, shows clearances of +/- 0.5 mm.

Also the cam disc is built in two parts. We usually design our engines with less clearance.

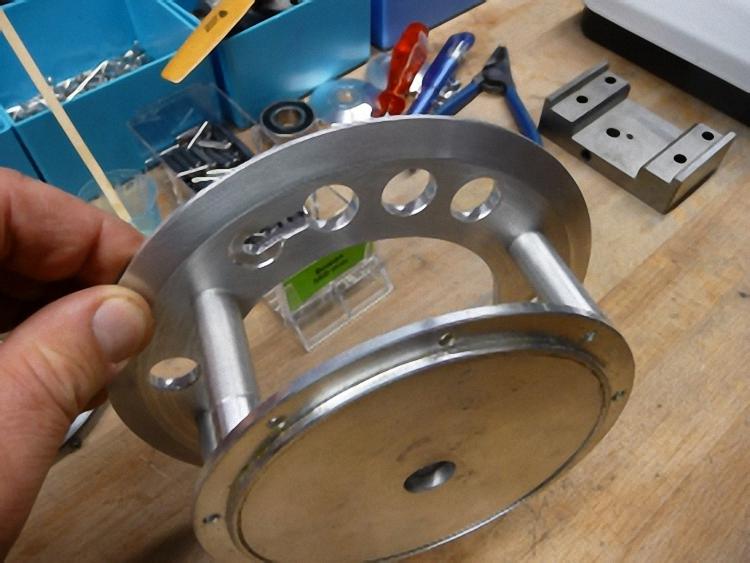

So we decided to build the cam disc from scratch. We dimensioned it afresh: lighter, a less thick running track, a thinner bearing seat, optimized timing and everything out of one piece.

Clear to see: thicker running track for the push rods, beveled gear ring, cam made out of one piece.

Here the piston ring did a good job. As the cylinder socket wasn’t completely round, it sliced off a chip right during the first test run. The cylinder was completely refinished.

The original surface of the engine case was glass-beaded and got a Scale Optic.

The front case part was unscrewed to remove the unwanted engraving. All the case parts were glass-beaded to create a natural surface. With a few oil stains the surface looks more and more realistic. All Allen-key case screws are replaced with stud bolts and nuts.

We replaced all standard installed bearings with German quality bearings.

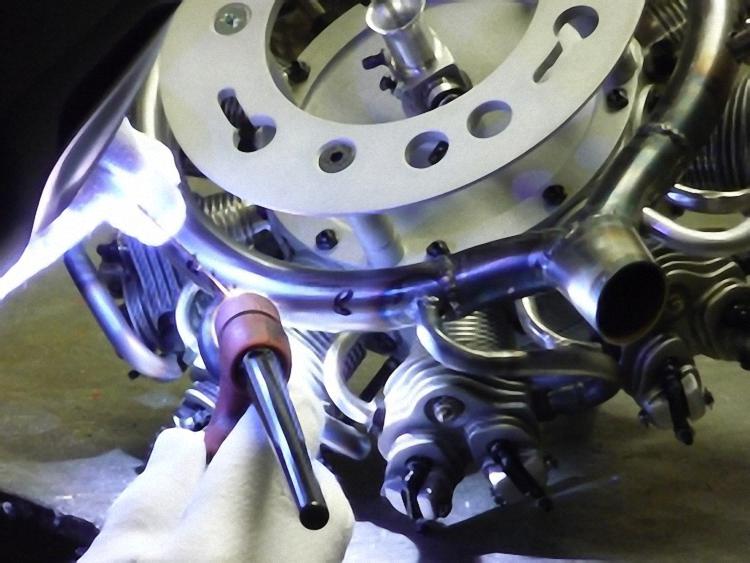

Now the assembly of the new cam disc begins.

Crank shaft freed from rust and assembly of the individual cylinders.

Now the true to scale PZL M-18 ring exhaust with the outlet on the side was still missing. Pipe elbows with the appropriate diameter were nowhere to be found. But for what are we a radial engine manufactory?

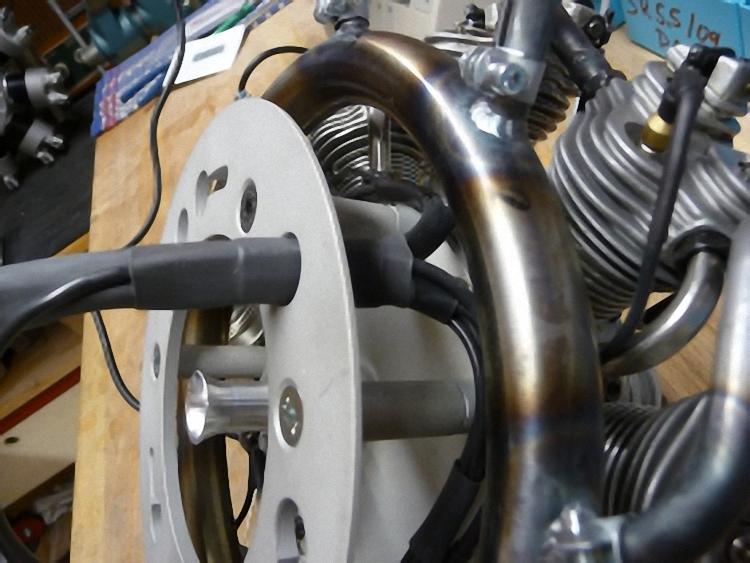

KELEO did the special ring production for us. The special design fit perfectly behind the engine mount.

Specially designed welding sockets and pipe elbows, bent with our mandrel pipe-bending machine.

We made specially bent exhaust pipes ... fitting, welding, ... small clamps complete the perfect scale optic ...

All parts are WIG-welded by a professional.

On request we have made our HS carbon push rods ourselves for the purpose of mass reduction and minimized wear of the cam disc.

This doesn’t also look good, it also has other advantages.

Of course this radial engine was also equipped with our special engine carrier with a bayonet joint.

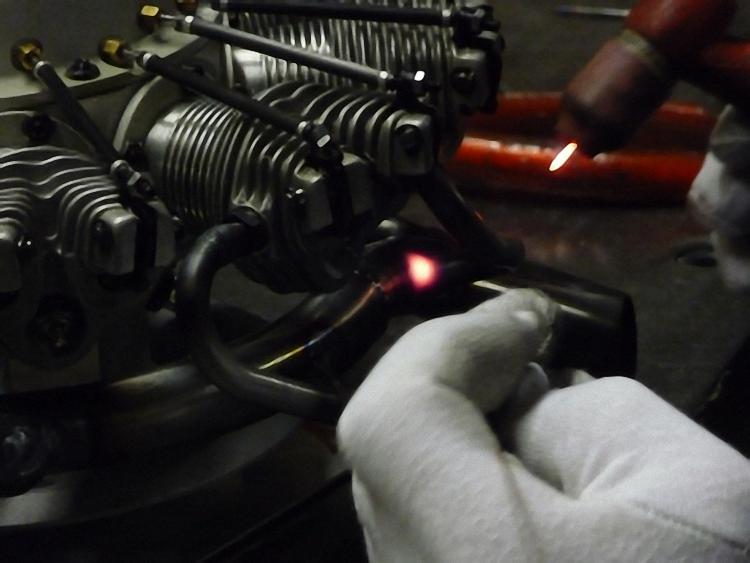

The engine received new glow plug connectors as well as a Hölzl glow plug regulator for a reliable operating performance.

The accurately laid harness is bundled in a central space.

All plug connectors are furnished with golden contact plugs and the right cross section.

The engine has optically turned into a real eye-catcher.

The valves can be adjusted precisely and therefore function reliably.

After about a year of work, the engine returns to its proud owner Friedrich Wolf.

We wish Friedrich Wolf good luck with the PZL M18 project.