October 2012- Construction Phase 3

Completing the cylinder heads

We decided to coat our rocker arms in red.

The brass sockets for the rocker arms are degreased and cleaned. They are now ready for pressing-in.

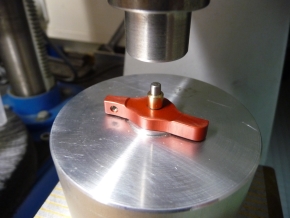

Pressing-in device with guide pin to position the brass sockets precisely into the rocker arms.

To improve the heat dissipation to the cylinder our sockets are chemically coated with a layer of nickel on the outside.

In two steps the sockets are pressed into the cylinders and then honed.

Here the balls are fitted into the rocker arms that later press on the valve stem.

Mounting the rocker arms into the cylinder heads. Not a chance without a magnifying glass.

The rocker arm shafts are made of CrNi steal, case-hardened and ground center less.

Here are the fully mounted rocker arms.

The cylinder heads are screwed together with the cylinder tubes and ready to be mounted into the engine cases.