November 2012 - Construction Phase 5

Merging cylinder modules and transmission modules

Back case with suction implementation and admission bearing for starter carrier.

All 18 cylinders suck in through the back case.

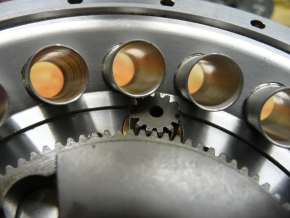

Pinion inboard with free rolling bearing. It’s a tight squeeze, but it fits!

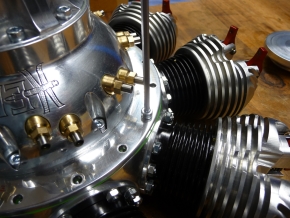

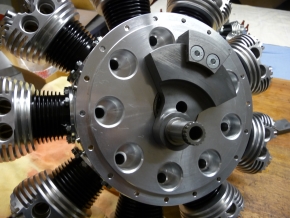

Assembling the front main bearing lid onto the first case with 9 cylinders.

The cam disc case with reduction gear (gear head) is screwed on.

Inner life of the front engine case.

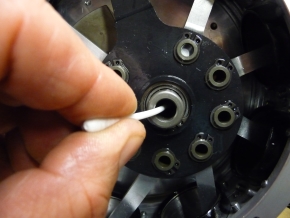

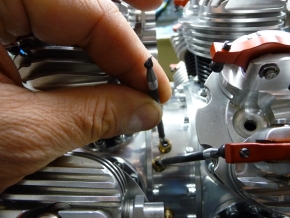

Cleaning the drill hole in the crankpins, as quite a lot accumulates with the pushing over the workbench during assembly ...

Leveling the sealing surface with an oilstone and then cleaning with thinner.

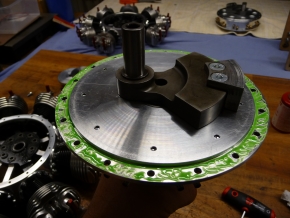

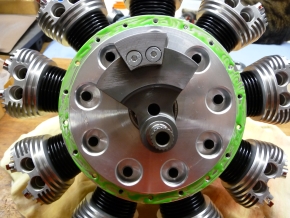

Center case with sealant (has to air dry for a little bit) – waiting for assembly.

Assembling center case onto front engine case.

Preparing the back engine case for assembly.

Sealing with liquid mixture.

Mounted engine case with center case.

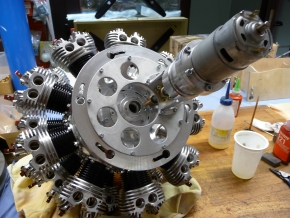

Now you can already imagine the dimensions.

Securing the back head connecting rod onto the crankpins with attached plug in gearing and lock washer.

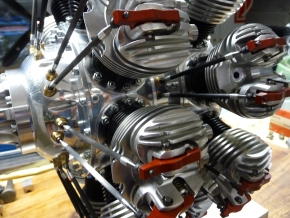

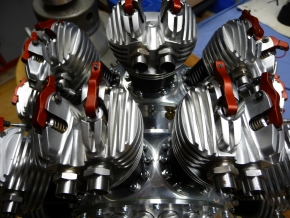

Fully mounted

A REAL GEM

Assembling the suction case onto the engine carrier as well as the integrated electro-starter.

Preparing the welding sockets for suction and exhaust, i.e. bending 18 intake manifolds as well as 18 exhaust manifolds that have to be fitted into ONE ring muffler.

Oiling the HS carbon push rods before assembly and, not to forget, oiling the valve heads.

Mounting the 36 HS carbon push rods ...

Finished for today ...